TYRE FLAT PROOFING

Our depot based tyre foam filling flat proofing service makes your pneumatic tyres solid, saving you from the costs of tyre repairs & machinery downtime. For a quote to flat proof your tyres please call our sales team on 0115 994 0900, or complete the quotation request form on this page.

Tyre foam filling allows you to combine the great selection of pneumatic tyres with the stability and puncture-proofing of solid tyres. Foam filled tyres cannot be punctured, avoiding costly downtime and tyre repairs or replacement. This makes them ideal for construction sites, landfills, scrap yards, recycling facilities and areas of rough terrain.

Your tyres are filled with specially designed polymer fluids that mix and cure to become solid. The tyres are filled to the manufacturer’s recommended pressure which will be retained for their entire service life, eliminating the need to check and maintain air pressure. This maintained air pressure can result in longer tyre tread wear and removes the risk of any dangerous explosive loss of air.

Big Tyres can supply you with the complete foam filled tyre package, including new wheel rims, tyres and foam filling. Alternatively, we can arrange to collect your existing tyre assemblies and just provide the foam filling service, as long as your exising assemblies are not punctured and are currently holding air pressure. Simply complete the quote request form on this page and our team will aim to reply with your bespoke flat proofing quote within one business day.

HOW DO THE TYRES GET FOAM FILLED?

The process of foam filling tyres involves pumping two seperate special polymer liquid compounds into the tyre cavity, which then combine and through a chemical reaction cure over a 24 hour period to become a solid foam/resin like material. The process involves specialist equipment and strict health and safety measures must be adherred to. The video below gives you a walk through example of how the process of tyre foam filling typically works.

DIFFERENT FOAM FILLING LIQUIDS

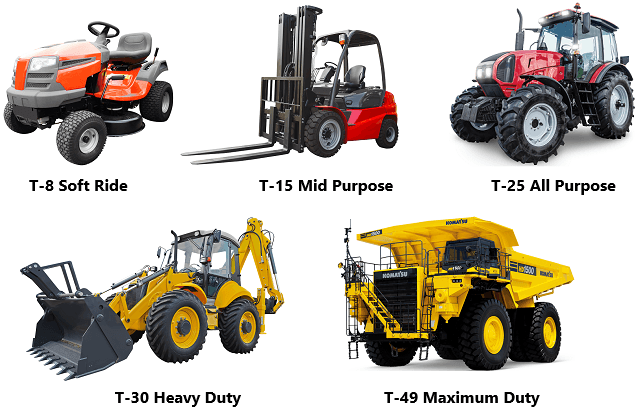

The quality of your foam filled tyres will depend on the experience and expertise of the staff trained to process your tyre, as well as the quality of the foam filling pumps and machinery used, and the quality and type of foam filling polymer liquids used during the foam filling process. Big Tyres ensure industry leading polymer liquids are used that have been tried and tested. The main liquids used in the market are 'Carpenter Rely' polmer solutions, and 'Carlisle TyrFill' polymer liquids. Sometimes the liquids come graded into categories specific to the type of machine or application the tyre is being used in, for example:

T-8 Soft Ride

- Maximum deflection

- Improved traction and footprint

- Gentle ride similar to air

- 35 MPH continuous

- Excellent shock absorption

- Excellent stability and safety

T-15 Mid Purpose

- Average duty

- Improved traction and footprint

- Excellent ride characteristics

- 35 MPH continuous

- Provides extra ballast

- Excellent stability and safety

T-25 All Purpose

- Heavy duty

- Industrial and Construction tyres

- Best heat resistance

- 35 MPH continuous

- Four hours at 55 MPH

- Balance between ride and carrying capacity

- Provides extra ballast

- Excellent stability and safety

T-30 Heavy Duty

- Heavy duty

- Industrial and Construction tyres

- Best heat resistance

- 35 MPH continuous

- Four hours at 55 MPH

- Better ride than T-49 but still capable of carrying heavy loads

- Excellent stability and safety

T-49 Maximum Duty

- Moving heavy weights over short distances

- Slow speed equipment

- Improved traction

- Special applications

- Extreme service

- Minimum deflection

- Excellent stability and safety

REQUEST A FILLING QUOTE

If you have any enquiries in regards to tyre foam filling then please Call Us on 0115 994 0900, or complete the 'Foam Filling Enquiry' form below as fully as possible for a bespoke quote. Our dedicated team will then price you for any new tyres, rims, valves, tyre assembling, polymer foam filling and collection and/or delivery as required.

Foam Filling Enquiry

If you have any questions about the information required or the foam filling process, then please Contact Big Tyres.

FREQUENTLY ASKED QUESTIONS

Here are some of the more common questions we get asked about our foam filling service. If you have any other question please do get in touch by phone or email.

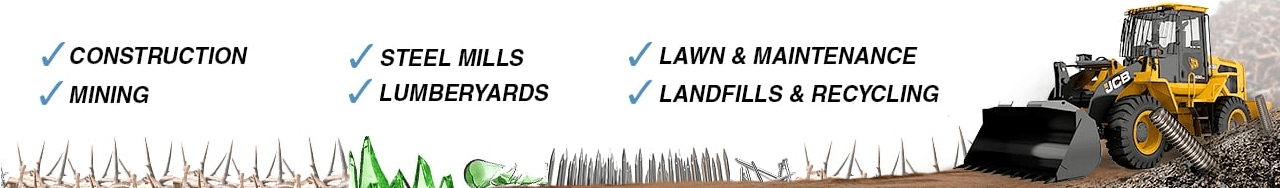

Generally it's plant, construction and industrial machinery like skid steers, dumpers, telehanders, excavators, loaders, scissor lifts, MEWP’s, rough-terrain forklifts, sweepers and tractors. There are not too many hard and fast rules except that they cannot be used on high-speed machines, as the heat build up at fast speeds can break down the foam filling material. Therefore, foam filling is not suitable for cars or high speed trailers. Foam Filling is also not suited to some lighter equipment like Quads, ATVs, UTVs as the extra weight of the filled units acting on the vehicles suspension and axles can leave them struggling to perform.

It depends on the amount of liquid fill that is needed to fill your tyre. Please give us your tyre size and we will quote based on the volume of liquid needed for that specific tyre size. Other costs are incurred if you require existing foam filled units to be re-conditioned, as we will charge to cut off and dispose of the existing filled material, to clean the rim and to fit the new replacement tyre ready for new fill to be applied. Collection charges for existing assemblies or rims and delivery charges to return filled units can also be incurred, or alternatively you may wish to drop off and collect the units on your own transport.

Yes. But they must currently be able to hold their required air pressure for at least 72 hours. We cannot work with punctured tyres as the liquid will escape before it is cured resulting in a loss of pressure. This leakage also results in a health and safety violation as additional clean up is required. We recommend our customer buy and use new tyres to ensure you have the maximum wearable tread on your newly foam filled units, as this will maximise your investments in the tyre foam filling due to the units life to likely now only be determined by the wear of the tyre.

It typically takes 5 working days. If the courier collects your current rims on Monday, we would usually receive them on Tuesday, we then fill and cure them for 24-48 hours and aim to dispatch them on Thursday for delivery back to you Friday. In the most part we would be ready to begin work within a couple of days of your request to quote / confirmed payment being received. On some occasions the work shops have a minor back log of jobs scheduled in, so If you are on a particularly tight schedule or need immediate work then please speak with our team to check how best we can accommodate your booking.

The liquid fill is pumped into the tyres at the normal operating pressure of the tyre being filled. If you have a specific tyre pressure you desire then please do inform us and we can usually achieve the same pressure with the liquid fill for you. This pressure will be retained for their entire service life of the tyre, eliminating the need to check and maintain air pressure. This maintained air pressure can result in longer tyre tread wear and removes the risk of any dangerous explosive loss of air.

No. Foam Filling the tyre doesn't change its load carrying capacity. The tyre pressure will be maintained however so the risk of your tyre being underflated is eliminated, which is a benefit as underflated tyres carry less load.

Yes. They are filled with a cured liquid so if you imagine fully filling your tyre with water say instead of air, the weight of the water in that case would be the additional weight now added. The polymer liquids are denser and heaver than water but its a good comparision. If you need to know the amount of liquid weight that has been, or will be, added to your tyre then we have guidance tables to help us advise you so please ask our sale team.

Firstly, as the tyres are now effectivey solid tyres you will not suffer from punctures and the down time and costs associated with them. The machine should be more stable due to the added weight of the foam filling material. You may find the ride and perfomance vary slightly due to the added weight, if you are in any doubt it is worth speaking with your specific machines dealer to find out its suitability for having filled tyres on it. Some machines like ATV's are not suited to the extra weight of the filled units as suspension and axles can struggle to perform with this added weight.

Yes. Normally, we collect you currently filled units and proceed to cut off the current tyre and foam from the wheel rim. We then clean up the wheel rim and fit the new tyres on to the rim and foam fill them as normal. The extra costs involve the time to cut off the existing filled tyres, and the fee's to dispose of the additional scrap material.